CNC Programming

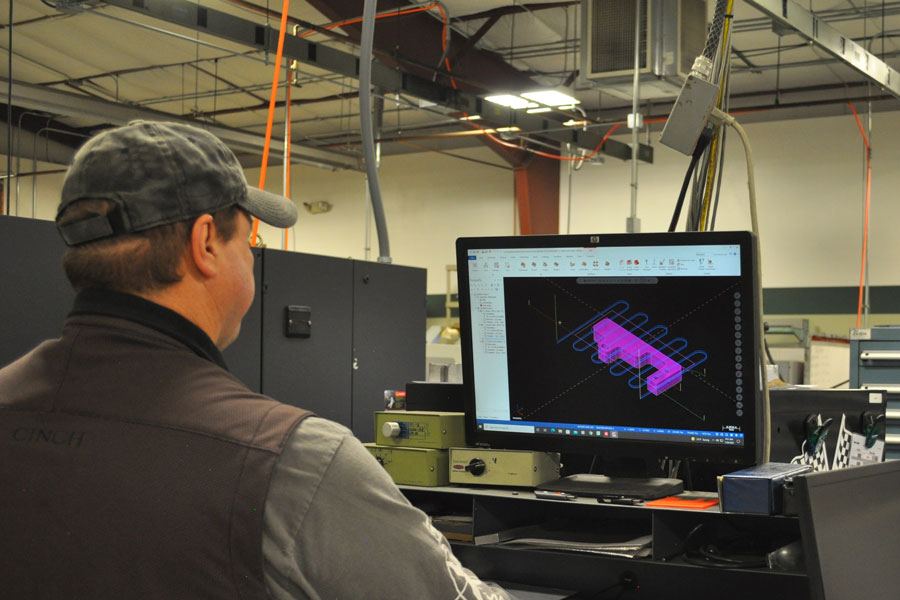

At IN-X Machine Inc., we take pride in offering high-performance CNC programming services that meet the evolving needs of modern manufacturing. As part of our commitment to precision, efficiency, and quality, we utilize MasterCam 2021 software, one of the most advanced tools in CNC programming. This software gives us an edge in delivering precision machining services across various industries, while significantly boosting production speed, flexibility, and cost-efficiency.

By leveraging MasterCam 2021’s state-of-the-art capabilities, we ensure that your designs are transformed into high-quality parts with exceptional accuracy. Whether your project requires simple 3-axis machining or complex 5-axis CNC machining, our team is equipped to handle even the most demanding challenges, ensuring that every job is completed to perfection.

MasterCam 2021: The Backbone of Our CNC Programming

Our investment in the latest MasterCam 2021 software reflects our dedication to offering cutting-edge CNC programming. This powerful software enables us to import and seamlessly integrate files from all major CAD systems, including:

- Catia

- ACIS

- IGES

- DXF

- VDA-FS

- Parasolid

- SolidEdge Files

- SolidWorks Files

This means that no matter the design platform you use, we can work with your files directly, avoiding the need for file conversions that can introduce errors or inefficiencies. The compatibility with a wide range of file formats allows us to work across industries such as aerospace, automotive, medical devices, and defense. Our goal is to provide you with CNC programming solutions that enhance both precision and workflow.

Advanced CNC Programming for Multi-Axis Machining

At IN-X Machine, our multi-axis CNC machining services stand out due to the advanced features of our MasterCam 2021 software. Multi-axis CNC machining allows us to move beyond the traditional X, Y, and Z axes, unlocking new possibilities for creating complex geometries and shapes. Here are some of the key benefits of our multi-axis CNC programming:

- Enhanced Precision: Multi-axis CNC machining provides the flexibility to machine parts from different angles in a single setup, improving the accuracy of the finished part. This reduces the risk of errors caused by repositioning the part multiple times.

- Improved Efficiency: By reducing the number of setups required for complex parts, we streamline the manufacturing process, cutting down on lead times and overall production costs.

- Lights-Out Production: Our CNC programming supports lights-out production, allowing machines to run unattended, which boosts efficiency and minimizes operational costs.

This advanced approach not only saves time and money but also ensures that the parts we produce are consistently high in quality.

CNC Programming for Turning Applications

For turning applications, we utilize MasterCam 2021’s enhanced features, such as improved support for modeling chuck jaws and chucks. This feature allows us to define these components by selecting a solid model, which gives us greater flexibility when programming for different machines. Additionally, our solutions for Swiss machining jobs use specialized post-processors, ensuring we generate precise G-code for our Swiss turning machines.

These capabilities make our CNC programming for turning applications highly accurate and versatile. We can handle everything from simple turning jobs to highly complex Swiss machining tasks with the same level of precision and attention to detail.

Advanced Drilling and Milling with CNC Programming

One of the standout features of MasterCam 2021 is its advanced drill tool path, which includes a customizable multi-segment drill cycle. This allows us to perform complex drilling operations such as back spot facing and multi-depth drilling with precision.

The new Chamfer Drill toolpath is another enhancement, allowing us to chamfer holes with perfect accuracy based on either the desired depth or width. These operations can be performed on different planes, allowing us to machine various holes with a single tool in one operation. This is a time-saving, precision-boosting feature that further enhances the quality of our CNC programming.

In addition, the bounding box wrap option allows us to create the smallest possible bounding box, optimizing material use and reducing waste. These efficiency improvements make our CNC programming services more environmentally friendly while also reducing costs for our clients.

CNC Machining Techniques: From 3-Axis to 5-Axis Precision

3-Axis CNC Machining

Our CNC programming expertise starts with the most fundamental form of CNC machining: 3-axis machining. This technique involves moving the cutting tool across the three primary axes—X, Y, and Z. While relatively straightforward, 3-axis machining remains a versatile and reliable method for a wide range of operations such as:

- Drilling precise holes

- Milling slots

- Cutting sharp edges

Although effective for many projects, 3-axis CNC machining may not offer the same level of complexity, speed, and precision as 4-axis and 5-axis machining.

4-Axis CNC Machining

For more intricate projects, 4-axis CNC machining adds an additional level of flexibility by rotating the workpiece along a fourth axis (A-axis), which is perpendicular to the X, Y, and Z axes. This additional axis enables more detailed machining operations such as:

- Rotating the workpiece for continuous cutting

- Performing more complex hole drilling on multiple planes

This extra capability is particularly useful when producing parts with complex geometries, where 3-axis machining would require multiple setups and reorientations.

5-Axis CNC Machining: Unmatched Precision and Efficiency

At IN-X Machine, we pride ourselves on offering the latest and most advanced CNC machining techniques with our 5-axis machines. The addition of two extra axes (typically the A and C axes) enables the cutting tool to approach the workpiece from virtually any direction, delivering unparalleled precision and speed.

Our 5-axis CNC machining is ideal for industries that require high levels of accuracy and complexity, such as:

- Medical devices

- Aerospace components

- Military equipment

- Energy sector machinery

5-axis machining allows us to manufacture highly detailed, intricate parts in a single setup, reducing production time and improving accuracy. By minimizing the need for multiple setups, we also reduce the risk of human error and increase the overall efficiency of the process.

Why Choose IN-X Machine for CNC Programming?

When you choose IN-X Machine for your CNC programming needs, you're partnering with a team that prioritizes innovation, precision, and quality. Our use of the latest MasterCam 2021 software ensures that we stay ahead of the curve in CNC programming technology, allowing us to provide you with faster turnaround times, reduced production costs, and superior quality parts.

Whether you need 3-axis machining for straightforward components or 5-axis machining for intricate designs, our team has the expertise and technology to deliver. From the medical industry to aerospace and beyond, we are your trusted partner in precision CNC machining.

Contact us today to learn how our CNC programming services can help you achieve your manufacturing goals with unmatched precision and efficiency.

IN-X Machine, Inc.

IN-X Machine, Inc.