CNC Production Machining

Our in-house CNC machines allow us to meet the needs of our customers, both large and small, with our ability to create and replicate parts and items with rapid efficiency.

Whether you need 10 parts or 10,000 parts, we can efficiently meet the needs of any milling or turning project.

In-X Machine specializes in CNC production machining of high precision parts for a range of industries including Medical, Aerospace, Defense, Technology, Auto, and more. Due to our specialized, state of the art lathes, mills, machine centers and finishing equipment. Producing CNC machined parts efficiently and precisely at a high volume isn’t a problem for us.

CNC Production Machining Capabilities

We can help you build a precise prototype and move to production with ease. Our CNC machine shop is capable of high volume milling and turning projects while maintaining speed and efficiency to job completion. Because we use a highly automated approach to CNC production machining we are able to reduce the labor involved saving our clients money in the long run.

CNC Milling Capabilities

Our CNC mills have the ability to create complex designs that require multi-axis machining through computer numerical control. These CNC mills can handle jobs that require cutting flat surfaces, drilling and boring holes, and more.

Since we are able to program our mills using CNC technology we can offer more precision and speed to job completion than any manually controlled mills could. Our CNC milling technology allows for 5-axis CNC production meaning it can cut 5 angels without the need to reprogram during operation.

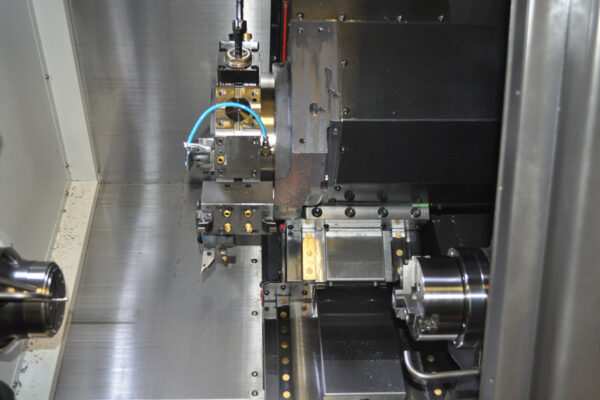

CNC Lathe Capabilities

Our CNC lathe machines or mill-turn lathes are advanced versions of CNC lathes that can handle more highly detailed projects and a fast rate. These machines differ from CNC milling machines due to the bar stock’s ability to move through a bushing using a sliding headstock, meaning the headstock will move forward and backward to expose only the area of the part that is currently being machined. Or that the part being machined is spinning while the tools are stationary around it.

This will increase the precision of the parts being machined while minimizing deflection.

While most people think these lathes and screw machines can only create screws or threaded parts. Our lathe capabilities can produce a wide variety of designs including very long parts with small diameters that are highly detailed and precise.

Finishing Capabilities

That last step in any production project is the finishing process applied to the parts to maintain consistency in look and functionality. We feature multiple vibratory finishers as well as an abrasive media blast cabinet to ensure your parts get the finish they deserve. When coupled with our quality assurance assessment tools you can rest assured that your parts will cut, finished, and inspected in a top-notch facility known for quality finished products.

IN-X Machine, Inc.

IN-X Machine, Inc.