Home

Our Services

IN-X Machine Inc.

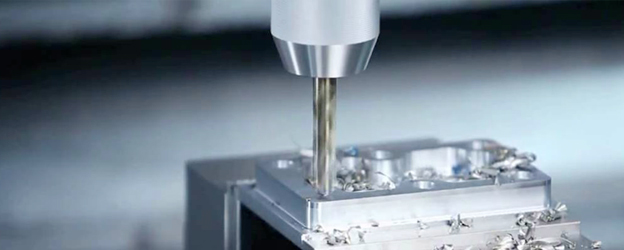

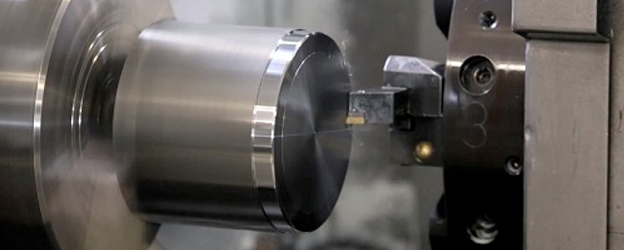

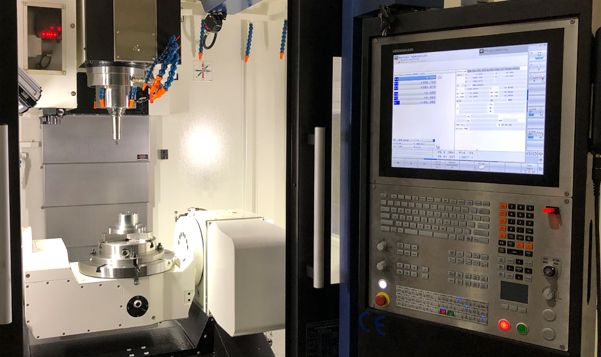

Our mission is to provide a diverse industrial customer base complete with streamlined sourcing, and to provide everything you need produce the best, most accurate components possible.

To achieve our mission, we use the best tools and most experienced machiners in the business, and to always remain totally dedicated to our customers - treating them like we ourselves would want to be treated.

IN-X Machine, Inc.

IN-X Machine, Inc.