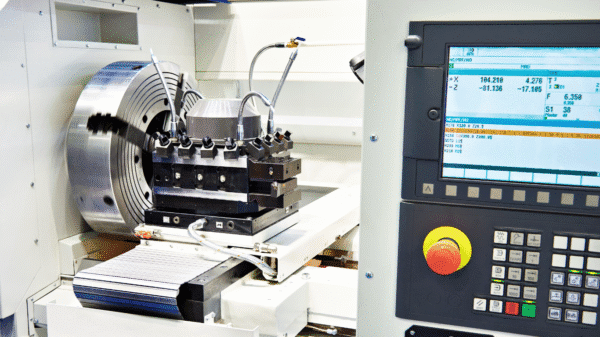

In today’s manufacturing world, precision CNC machining stands at the heart of innovation. As 2026 continues to unfold, machine shops are leveraging smarter tools, deeper automation, and more advanced materials to deliver parts with exceptional accuracy, speed, and cost-efficiency. For companies seeking high-quality components with repeatable precision, understanding the modern landscape is key.

What’s New in Precision CNC Machining

Precision CNC machining has evolved rapidly in recent years, driven by digitalization and smarter factory systems. One major shift is deeper automation paired with robotics: machine shops are now deploying robotic loading/unloading, automated pallet changers, and lights-out machining routines that run with minimal human intervention. These innovations reduce errors and downtime, and free up skilled staff to focus on oversight and optimization.

Another major trend is the integration of artificial intelligence and machine learning. Modern CNC platforms collect vast amounts of data—spindle loads, tool wear, part finish metrics—and AI systems analyze that data to predict tool failure or optimize cut paths. In practical terms this means fewer unplanned stops, more consistent surface finishes, and lower scrap rates, all of which boost the value of precision CNC machining.

Materials and tooling have also advanced. High-performance tool materials such as cubic boron nitride (CBN) and polycrystalline diamond (PCD) are now more common in machining hard alloys and composites. Meanwhile, precision CNC machining shops are published in governing markets with materials like carbon-fiber composites, titanium alloys and advanced aluminum-lithium alloys that demand ultra-tight tolerances and specialized tool paths.

Key Trends Shaping the Future

1. Multi-Axis and Hybrid Machining

Complex geometries are increasingly produced with 5-axis and even 6-axis machines. These machines allow par ts to be machined in one setup, reducing error-prone repositioning and setup time. According to industry-watchers, the upcoming International Manufacturing Technology Show (IMTS) 2026 will showcase new models of 5-axis machines with integrated pallet changers and high-speed direct-drive rotary axes. In addition, hybrid manufacturing—blending subtractive (CNC) and additive (3D-printing) processes—is gaining momentum. By combining additive build with precision CNC finish, shops can create complex near-net-shape parts and then machine them to tight tolerances.

ts to be machined in one setup, reducing error-prone repositioning and setup time. According to industry-watchers, the upcoming International Manufacturing Technology Show (IMTS) 2026 will showcase new models of 5-axis machines with integrated pallet changers and high-speed direct-drive rotary axes. In addition, hybrid manufacturing—blending subtractive (CNC) and additive (3D-printing) processes—is gaining momentum. By combining additive build with precision CNC finish, shops can create complex near-net-shape parts and then machine them to tight tolerances.

2. Smart Manufacturing & Sustainability

The role of precision CNC machining is increasingly tied to smart manufacturing strategies. Internet of Things (IoT) sensors, predictive analytics, and digital twin technologies allow real-time monitoring of machine health and part quality. For example, digital twin simulations of tool paths can identify potential collisions or vibrations before any metal is cut.

Sustainability is also front and center. Machining shops are implementing minimum-quantity lubrication (MQL), recycling scrap metal, and optimizing nesting software to minimize waste. Multi-axis CNC systems now support machining of recycled alloys, and energy-efficient drives reduce power draw per component.

3. Market Growth & Strategic Reshoring

Globally, the market for CNC machines is projected to hit around USD 93 billion in 2026, with a strong compound annual growth rate driven by demand for precision manufacturing. This growth reflects not only new machine sales but also investments in upgrades of existing systems, especially in aerospace, medical, and advanced mobility sectors.

In parallel, many firms are reshoring manufacturing and bringing precision CNC machining operations closer to end-customers to reduce lead time, supply-chain risk and logistics cost.

Why It Matters for Your Business

Choosing precision CNC machining today means more than just high accuracy—it means aligning with manufacturing trends that prioritize flexibility, sustainability, and smart operations. Whether you’re producing aerospace brackets, medical-device housings or high-performance automotive components, machining partners who invest in 5-axis machines, predictive analytics and hybrid processes will deliver parts faster, with fewer defects and at more predictable cost.

As competition increases and tolerances become tighter, machining capability becomes a strategic advantage. By partnering with a machine shop committed to the latest precision CNC machining technologies, you secure not just parts—but future-proof manufacturing capacity.

Looking Ahead into 2026 and Beyond

As the industry accelerates into 2026, precision CNC machining will continue to evolve—faster machines, smarter controls, and more sustainable operations will become mainstream. Tooling will push into nano-scale finishes, digital twins will simulate entire production lines, and hybrid machining will redefine what’s possible.

Staying informed about these developments and working with a forward-looking partner will allow you to stay ahead of the curve. In the age of precision manufacturing, adaptability, innovation and quality aren’t optional—they’re essential.

IN-X Machine, Inc.

IN-X Machine, Inc.