In today’s fast-paced digital world, the demand for high-quality electronic components has skyrocketed, fueled by rapid advancements in technology and the increasing complexity of electronic devices. With the push for smaller, more efficient, and highly reliable components, precision manufacturing has become paramount. Among the various manufacturing processes available, CNC (Computer Numerical Control) machining stands out as the premier solution for producing intricate and high-precision electronic components. CNC machining has become the industry standard for creating parts that meet tight tolerances, making it an invaluable resource in the electronics sector. In this post, we’ll dive into the benefits of CNC machining for electrical components, compare it to other production methods, and highlight its versatile applications in the electronics industry.

Key Advantages of CNC Machining for Electronic Components

Key Advantages of CNC Machining for Electronic Components

When it comes to manufacturing components with a high level of precision and reliability, CNC machining offers several unique advantages. These benefits make it ideal for producing the intricate parts required in modern electronics.

1. High Precision and Accuracy

CNC machining is a highly accurate process. Machines are guided by computer-programmed instructions, enabling them to produce intricate shapes and fine details with extremely tight tolerances. This level of precision is especially important for electronic components, where even a minor deviation can compromise the entire device’s functionality. With CNC machining, manufacturers can consistently achieve the necessary precision required to keep today’s electronics performing at their peak.

2. Consistency and Repeatability

For large-scale production, consistency and repeatability are essential. CNC machines are designed to replicate the exact specifications repeatedly without variation. This is critical for producing electronic components that must meet specific quality standards, as any inconsistency can result in performance issues. Whether it’s producing hundreds or thousands of units, CNC machining provides the reliability that electronics manufacturers need to ensure each component functions as intended.

3. Material Versatility

Another advantage of CNC machining for electrical components is its ability to work with a wide array of materials. CNC machines can handle metals, plastics, and composites, giving manufacturers the flexibility to choose the best material based on the component’s performance requirements. For instance, metal components like aluminum and copper can be used for their conductivity and durability, while plastics may be chosen for lightweight housing and insulation. This versatility in material selection makes CNC machining a one-stop solution for a variety of electronic component needs.

4. Reduced Waste and Improved Efficiency

CNC machining is a subtractive manufacturing process, meaning material is removed from a larger piece to create the final shape. This process is highly efficient, minimizing material waste compared to additive methods, such as 3D printing. Additionally, because CNC machining is controlled by a computer, it ensures material is used with precision, which helps reduce costs and supports sustainable practices. For industries focused on high-volume production, this efficiency makes CNC machining an economically viable option.

CNC Machining for Electronic Components vs. Other Manufacturing Processes

While other methods like injection molding, die casting, and 3D printing have their place in the manufacturing industry, CNC machining often provides superior results for high-precision electronic components. Here’s how it compares:

Injection Molding and Die Casting

Both injection molding and die casting are cost-effective for mass-producing large quantities of parts. However, these methods have limitations when it comes to producing highly complex shapes with tight tolerances. CNC machining, on the other hand, excels in creating intricate designs that meet the exact specifications necessary for delicate electronics. While injection molding and die casting are ideal for simpler, high-volume parts, CNC machining remains the preferred choice for components that require precision and detail.

3D Printing

3D printing has gained popularity for creating prototypes and producing complex shapes without the need for tooling. However, it falls short in terms of achieving the same level of surface finish and accuracy as CNC machining. Additionally, 3D printing is limited in its material choices, whereas CNC machines can work with a broad range of metals and plastics. For projects that require both precision and flexibility in materials, CNC machining is often the superior choice.

Applications of CNC Machining in the Electronics Industry

CNC machining is used in various applications within the electronics industry, including:

- Printed Circuit Board (PCB) Components: CNC machines can produce the intricate components and connectors required for PCBs with precision and accuracy, ensuring optimal performance and longevity.

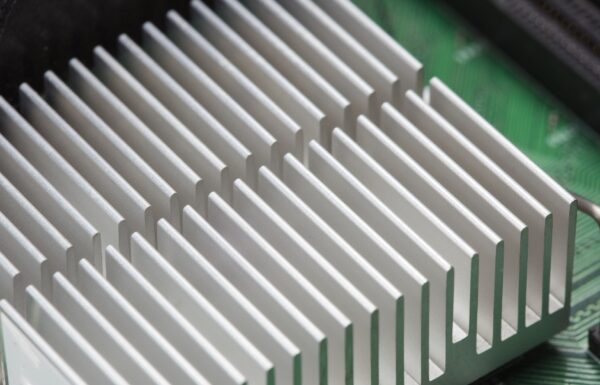

- Heat Sinks: CNC machining can create heat sinks with complex geometries and tight tolerances, which are crucial for dissipating heat and maintaining the performance of electronic devices.

- Enclosures and Housings: CNC machines can produce high-quality enclosures and housings for electronics devices, providing protection and structural support while maintaining a sleek and aesthetically pleasing appearance.

- Custom Components: CNC machining can be utilized to produce custom electronics components for unique applications or prototypes, allowing manufacturers to test and iterate designs quickly and efficiently.

IN-X Machine, Inc.

IN-X Machine, Inc.