The world of medicine is rapidly evolving. New technologies are arriving to the scene with every passing day, and recent years have proved to be hugely influential on the world of medicine, and hugely indicative of the industry’s future. What’s readily apparent, is that innovation in medicine is not slowing down, and to keep up to speed with the industry’s biggest names, firms like your’s will require a production partner that can keep pace with big names.

Manufacturing modern medical components requires a laser-accurate and highly efficient parts fabricator, one that utilizes a process known as CNC machining. In this article, we’ll walk you through what CNC machining is, and why CNC medical industry is a natural fit for the field.

What Is CNC Machining?

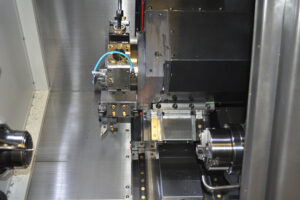

The most popular and most effective method for mass producing highly-precise parts, CNC machining utilizes computer-guided machining instruments that process metals, plastics, and other materials leagues faster than any human.

A CNC machine’s computerized instruction set means it can make extremely fine modifications and impressive speed and scale. These sets of instructions can reliably create machined parts accurate down to .0001, meaning any theoretical mistake a CNC machine would make would be no larger than that. Precision of this magnitude is absolutely essential for any medical device manufacturer, because, as any medical professional can tell you, when it comes to the human body, there is very little room for error.

What’s more, is that CNC machining can be done on a large scale. You’d be forgiven for thinking that, due to such small margins of error, CNC machining would mean a rather long turnaround time per part – a long period of time between metaphorically pressing “go” and receiving a finished product. While parts of especially high tolerance may well require long fabrication times, CNC machine shops, like IN-X Machine, Inc., have proprietary ways of making your turnaround times surprisingly short.

From skilled technicians to finely-tuned machines, the best CNC machine shops are professionals at getting you your components in record time. And when you sign on with a shop like IN-X, you can enjoy 24/7 part production thanks to our “Lights-Out” production scheme. So called because our machines operate all throughout the night, after our staff shut off the lights, so to speak, Lights-Out production means we can provide some of the best turnaround times in the industry.

CNC Machining in the Medical World

CNC-machined parts can be found in the vast majority of, and a still-increasingly high number of medical components. From surgical instruments to pacemakers to hip replacements, CNC-machined parts help make up the backbone of many individuals’ health – both metaphorically, and sometimes literally.

As previously mentioned, tight tolerances, or small margins of error, are crucial for the proper function of medical devices and instruments. The tighter the tolerance of any given component, the better it can be expected to function, meaning better outcomes for patients and a better reputation for your parts and business. Finding a CNC medical industry partner that meets your device’s minimum estimated tolerance is critical, and finding one that can improve upon that tolerance is greatly preferred.

When fractions of fractions of a millimeter count, you’ll need the best of the best. At IN-X, our devices, like our CNC Swiss Turning machine, can manufacture to .0001, one of the best figures of any CNC machine shop. Combine this with our machine centers, saws and finishing equipment, you’ll find we’re one of the best, most flexible partners in the greater Denver CNC world.

What To Look For in a CNC Medical Industry Partner

Beyond the aforementioned tight tolerances and high production volume, there are several things that you’ll want to consider in a CNC medical industry partner for your firm.

First, consider what materials your components will be made of. Which types of plastics, metals, or other compounds will be incorporated into your device, instrument, or other miscellaneous part? You’ll want to confirm that your CNC medical industry partner works with those types of materials, and that they can do so an efficient, reliable manner. Unfortunately, not all CNC machine shops are created equal – some are less capable than others.

You will also want to ensure the safe, sterile fabrication environment of your components. This is especially true of the medical industry, as any contaminants at all are often, if not always, flat-out unacceptable. Other CNC machine shops often don’t have the facilities necessary to create parts to that degree of sterility, so choose your CNC medical industry partner carefully.

IN-X Machine, Inc.

IN-X Machine, Inc.