CNC production machining is a pivotal process in modern manufacturing, crucial for producing high-precision metal and plastic components. Utilizing sophisticated computer numerical controls (CNC), this method is renowned for its accuracy and efficiency, making it indispensable in various industries. Known for high-speed production and quick turnaround times, CNC production machining is the backbone of precision manufacturing. This comprehensive guide delves into the intricacies of CNC production machining, highlighting its significance in today’s industrial landscape.

Delving into CNC Production Machining

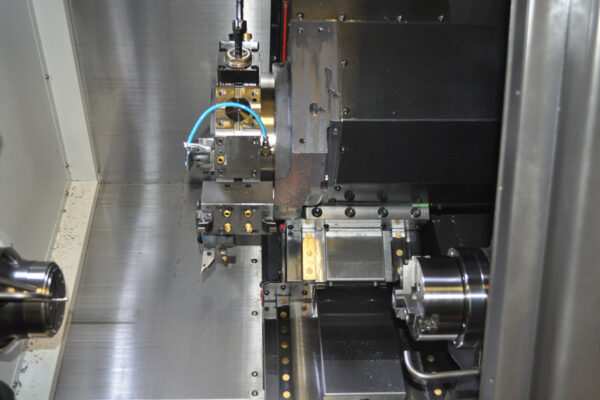

CNC production machining involves the use of computer-controlled machinery to fabricate components with exceptional precision. The heart of this process lies in computer numerical control programs that command the machining tools, ensuring meticulous accuracy.

This technology is integral in producing a diverse range of products for industries such as aerospace, defense, automotive, medical devices, transportation, energy, heavy equipment manufacturing, and industrial automation. It is important for making precise parts like gears, bearings, shafts, springs, wire forms, and sheet metal parts. It is used in processes like milling and turning.

Tight Tolerances in CNC Machining: A Necessity

In CNC production machining, maintaining tight tolerances is not just a preference but a requirement for ensuring the highest quality of the final product. The precision of a CNC machine directly correlates with its ability to produce components that meet exact specifications. Tighter tolerances are especially critical for complex, integral components, as they guarantee the part’s performance and safety standards. This level of precision is what sets CNC production machining apart from other manufacturing processes, making it a preferred choice for industries where accuracy is paramount.

Innovations in CNC Machining: Lights-Out Production

Lights-out production represents a significant advancement in the field of CNC production machining. This concept refers to the ability of CNC machines to operate autonomously, without human supervision, often during non-working hours. Such automation has transformed the manufacturing landscape, enabling continuous production and significantly reducing labor costs and production time. Especially beneficial in high-volume sectors like aerospace and automotive manufacturing, lights-out production allows for uninterrupted manufacturing cycles, enhancing overall efficiency and output.

Choosing IN-X Machine for CNC Production Machining

IN-X Machine, located in Arvada, is a leader in providing CNC production machining services. Our facility boasts an array of state-of-the-art machinery, including CNC milling, CNC turning, and Swiss turning, mirroring the capabilities of the most advanced machine shops globally. We are experts in finishing parts, making sure each component meets or surpasses the highest standards in surface inspection and measurement. Our commitment to quality and precision makes us an ideal partner for your CNC production machining needs.

If you’re in search of expertise, IN-X Machine is your go-to solution. Our team is ready to assist you with your project requirements, offering personalized consultation and answering any questions you may have. Contact us today to explore how we can contribute to the success of your manufacturing endeavors with our top-notch CNC production machining services.

IN-X Machine, Inc.

IN-X Machine, Inc.