In aerospace manufacturing, precision isn’t just important—it’s critical. From massive fuselage sections to tiny fasteners, every component must meet rigorous standards to ensure safety and performance. Even the smallest error can have serious consequences in flight.

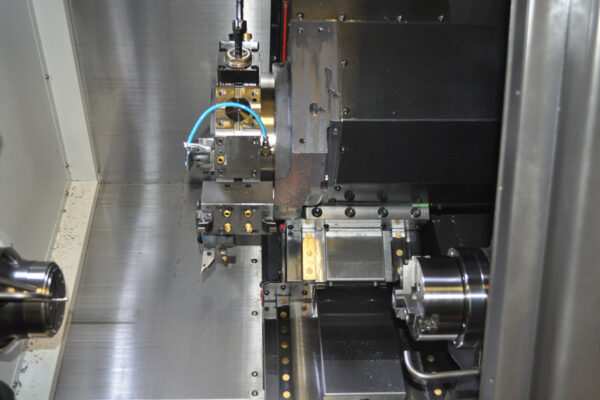

Aerospace CNC Machining refers to the utilization of Computer Numerical Control (CNC) technology to develop aerospace components. This technology allows for automated control of machining tools with an unparalleled level of precision, operated via computer programming. The aerospace sector’s complex, intricate designs and the demand for flawless manufacturing make CNC machining an invaluable asset.

What Sets Aerospace CNC Machining Apart

CNC machining uses computer-controlled tools guided by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to produce precise components. Aerospace applications push this technology to its limits, demanding ultra-tight tolerances, specialized materials, and flawless consistency.

Here’s what makes CNC machining invaluable in the aerospace industry:

Extreme Precision: Machines achieve tolerances measured in microns, critical for safety and functionality.

Extreme Precision: Machines achieve tolerances measured in microns, critical for safety and functionality.- Material Versatility: Works with aerospace-grade metals like titanium, stainless steel, and aluminum, as well as high-performance polymers.

- Consistency at Scale: Produces identical parts repeatedly to meet strict FAA and global compliance standards.

- Faster Innovation: Enables rapid prototyping to bring new designs to market quickly.

- Cost Efficiency: Reduces waste and lowers labor costs through automation and optimized cutting paths.

These factors make CNC machining a perfect fit for industries like commercial aviation, defense, and space exploration.

Key Benefits of Aerospace CNC Machining

While precision is the headline benefit, aerospace CNC machining brings a wide range of advantages to manufacturers and engineers.

1. Speed and Scalability

Time is money in aerospace production. CNC machining:

- Speeds up prototyping, allowing engineers to test and refine designs quickly.

- Seamlessly shifts to full-scale production without sacrificing quality.

- Keeps projects on schedule even with complex parts and tight deadlines.

2. Cost Optimization

Aerospace-grade materials, like titanium, are expensive. CNC machining helps control costs by:

- Minimizing material waste through precision cutting.

- Automating complex processes to reduce labor expenses.

- Limiting rework by ensuring consistent, accurate results the first time.

This balance of efficiency and accuracy makes it a smart long-term investment for aerospace companies.

3. Advanced Technology Integration

Modern CNC machines use advanced software to:

- Monitor production in real-time for improved quality control.

- Execute five-axis machining, allowing for complex geometries impossible with traditional methods.

- Continuously refine workflows to improve efficiency and reduce production bottlenecks.

This integration empowers manufacturers to stay ahead of technological advancements and maintain a competitive edge.

Why Aerospace CNC Machining Is the Future

As sustainability and innovation continue to shape the aerospace industry, CNC machining is evolving to meet new demands. Manufacturers are increasingly focused on reducing their environmental footprint by incorporating recyclable metals and adopting greener practices throughout production. Many facilities are also investing in energy-efficient machines, which help lower operational costs while promoting more sustainable operations.

In addition to these eco-friendly initiatives, advanced digital technologies are transforming the way aerospace components are designed and manufactured. Digital twin technology, for example, allows engineers to simulate and refine designs virtually before cutting a single piece of material. These innovations position aerospace CNC machining not only to meet today’s challenges but also to drive the industry toward a cleaner, smarter, and more efficient future.

Precision That Lifts the Aerospace Industry

Aerospace CNC machining is more than a manufacturing process—it’s a key driver of safety, innovation, and efficiency. With its ability to handle complex designs, high-performance materials, and strict quality standards, it ensures that every aerospace component is built for reliability.

Aerospace CNC machining is more than a manufacturing process—it’s a key driver of safety, innovation, and efficiency. With its ability to handle complex designs, high-performance materials, and strict quality standards, it ensures that every aerospace component is built for reliability.

As technology progresses, CNC machining will continue to push boundaries, helping aerospace companies meet modern challenges and take flight into the future.

IN-X Machine, Inc.

IN-X Machine, Inc.