In the dynamic world of industrial operations, production manufacturing stands as a cornerstone for creating quality products at scale. At In-X Machine, Inc., we offer top-notch production manufacturing services tailored to our clients’ needs.

We offer high-quality services that can be customized to meet a variety of requirements. We take pride in providing manufacturing solutions that are specifically designed to meet the unique needs of each client. This article delves into the intricacies of production manufacturing, the state-of-the-art equipment we utilize, and how our services can elevate your manufacturing processes.

What is Production Manufacturing?

Production manufacturing is the process of transforming raw materials into finished goods through a combination of machinery, tools, and labor. This method is essential for producing large quantities of items consistently and efficiently. Unlike custom manufacturing, which focuses on creating unique products in smaller quantities, production manufacturing emphasizes standardization, quality control, and scalability.

Key Aspects of Production Manufacturing

Standardization

One of the primary goals of production manufacturing is standardization. By producing standardized products, manufacturers can ensure that every item meets the same specifications and quality standards. This uniformity is crucial for industries where consistency is vital, such as automotive, aerospace, and consumer electronics.

Efficiency

Efficiency is at the heart of production manufacturing. The processes are designed to maximize output while minimizing waste and costs. This involves optimizing every step of the manufacturing process, from raw material procurement to final assembly. Efficient production not only reduces costs but also shortens lead times, allowing businesses to respond more quickly to market demands.

Scalability

Scalability is another key aspect of production manufacturing. As market demands fluctuate, manufacturers must be able to adjust their production capacities accordingly. Scalable manufacturing processes allow for seamless transitions between different production volumes, ensuring that quality remains consistent regardless of the quantity produced.

Quality Control

Quality control is integral to production manufacturing. Rigorous testing and inspection protocols are implemented at various stages of the manufacturing process to maintain high standards. Quality control measures help identify and rectify defects early, preventing faulty products from reaching the market and ensuring customer satisfaction.

Equipment Used in Production Manufacturing

At In-X Machine, Inc., we leverage cutting-edge equipment to deliver superior production manufacturing services. Our facility is equipped with advanced machinery that enables precision, efficiency, and reliability. Here’s a detailed look at some of the key equipment we use:

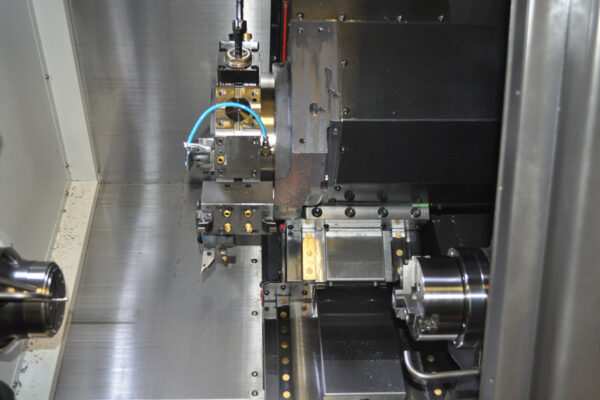

CNC Machining Centers

Our Computer Numerical Control (CNC) machining centers are at the heart of our production capabilities. These machines allow for precise control of various manufacturing processes, including drilling, milling, and turning. CNC machining centers are highly versatile and can produce complex parts with tight tolerances, ensuring consistency across large production runs. The automation capabilities of CNC machines also enhance efficiency by reducing manual intervention and human error.

Injection Molding Machines

For plastic components, our injection molding machines offer unparalleled efficiency and precision. This equipment allows us to produce high volumes of plastic parts quickly and cost-effectively, making it ideal for industries such as automotive, consumer goods, and electronics. Injection molding is particularly suited for producing parts with intricate geometries and fine details, ensuring that every piece meets exact specifications.

Laser Cutting Systems

Our laser cutting systems provide precision cutting for a wide range of materials, including metals, plastics, and composites. This technology enables us to create intricate designs and complex shapes with minimal waste, enhancing the efficiency and quality of our production processes. Laser cutting is ideal for applications requiring high precision and clean edges, such as aerospace components and medical devices.

Robotic Automation

To further streamline our manufacturing operations, we employ robotic automation systems. These robots handle repetitive tasks with high accuracy, reducing the risk of human error and increasing overall productivity. Automation also allows us to maintain a consistent production rate, even for large-scale orders. Robotic systems can perform tasks such as assembly, welding, and material handling, ensuring that production remains efficient and reliable.

Our Production Manufacturing Services

At In-X Machine, Inc., we offer a comprehensive suite of production manufacturing services designed to meet the unique needs of our clients. Our services include:

Precision Machining

Utilizing CNC technology, we produce high-quality metal and plastic parts with exacting tolerances. Our precision machining capabilities ensure that every component meets stringent quality standards, making us a trusted partner for industries that demand reliability and accuracy. Whether it’s prototypes or high-volume production, our machining services are tailored to meet diverse manufacturing requirements.

Injection Molding

Our injection molding services are designed to manufacture large volumes of plastic components with precision and efficiency. We work with various thermoplastics and thermosetting polymers, providing solutions for diverse applications. Our expertise in injection molding allows us to produce parts with complex geometries, ensuring that every piece meets the required specifications and standards.

Assembly Services

We provide complete assembly solutions, from simple sub-assemblies to complex final products. Our assembly services make manufacturing easier by ensuring all components fit together perfectly and work as they should. By handling assembly in-house, we can maintain tight control over quality and deliver fully assembled products ready for use.

Quality Assurance

Implementing stringent quality control measures is a cornerstone of our manufacturing philosophy. Our quality assurance protocols include thorough inspections, testing, and validation at every stage of production. This ensures that every product leaving our facility meets the highest standards of quality and reliability. Our commitment to quality assurance helps us build long-term relationships with our clients, who trust us to deliver products that meet their exacting standards.

Prototyping

We offer rapid prototyping services to help clients validate designs before full-scale production. Our prototyping capabilities allow for quick iterations and adjustments, ensuring that the final product meets all design requirements. By providing detailed prototypes, we help our clients visualize and refine their concepts, reducing the risk of costly changes during mass production.

Why Choose In-X Machine, Inc.?

Choosing In-X Machine, Inc. for your production manufacturing needs means partnering with a company committed to excellence, innovation, and customer satisfaction. Our experienced team, state-of-the-art equipment, and dedication to quality make us the ideal choice for businesses looking to enhance their manufacturing capabilities. Here are some reasons to choose us:

- Expertise: With years of experience in the manufacturing industry, our team has the knowledge and skills to tackle even the most challenging projects.

- Advanced Technology: We invest in the latest manufacturing technologies to ensure that our clients receive the best possible products.

- Customization: We work closely with our clients to understand their unique needs and provide customized solutions that meet their specific requirements.

- Customer Service: Our commitment to customer satisfaction means that we go above and beyond to ensure that our clients are happy with our services.

Conclusion

Production manufacturing is a critical component of modern industrial operations, enabling companies to produce high-quality products at scale. At In-X Machine, Inc., we use advanced machines and experienced professionals to offer customized manufacturing services.

Our team of skilled experts ensures top-notch quality in every project. We tailor our services to meet your specific needs and requirements. Whether you require precision machining, injection molding, or assembly services, our team is ready to help you achieve your production goals efficiently and effectively.

By leveraging the expertise and capabilities of In-X Machine, Inc., you can ensure your production processes are optimized for success. Let us help you transform your manufacturing operations and achieve new levels of productivity and quality.

IN-X Machine, Inc.

IN-X Machine, Inc.