In the sophisticated realm of aerospace, every component crafted holds significance, from the largest fuselage sections to the smallest brackets. Each part must adhere to stringent precision and quality standards because of the high-stakes nature of the aerospace industry. Aerospace CNC Machining is important for precision in making aerospace components. It has a reputation for reliability and accuracy.

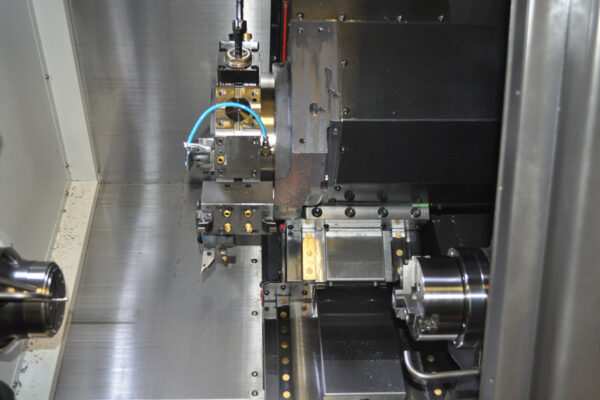

Aerospace CNC Machining refers to the utilization of Computer Numerical Control (CNC) technology to develop aerospace components. This technology allows for automated control of machining tools with an unparalleled level of precision, operated via computer programming. The aerospace sector’s complex, intricate designs and the demand for flawless manufacturing make CNC machining an invaluable asset.

Here are several key facets of Aerospace CNC Machining that spotlight its indispensability in the aerospace sector:

Unwavering Precision:

The aerospace industry necessitates a level of accuracy that leaves no room for error. Aerospace CNC machining offers this unwavering precision, ensuring each component is manufactured to the exact specifications, which is critical for the safety and functionality of aerospace equipment.

Material Versatility:

Material Versatility:

Aerospace parts need special materials like titanium, aluminum alloys, or high-quality plastics to meet industry’s high standards. Aerospace CNC machining is adept at handling a variety of materials, ensuring optimum structural integrity and performance of the produced parts.

Cost Efficiency of Aerospace CNC Machining:

While the initial setup cost can be substantial, its ability to automate complex processes results in significantly reduced labor costs over time. Moreover, the reduction in errors leads to less material wastage, making it a cost-effective solution in the long run.

Rapid Prototyping and Production:

Time is often of the essence in the aerospace industry, with tight deadlines and high output expectations. Aerospace CNC machining accelerates the production cycle, offering rapid prototyping and production capabilities while retaining high-quality outputs.

Consistent Quality:

The reproducibility of the machining ensures that every component, from the first to the last, meets the specified quality standards. This consistency is crucial for adhering to the stringent quality control requirements prevalent in the aerospace sector.

Advanced Technology Integration:

The integration of modern software with Aerospace CNC machining allows for sophisticated design capabilities, real-time monitoring, and enhanced operational efficiency. This technological synergy fosters an environment where continuous improvement and innovation thrive.

Customization and Scalability:

Aerospace CNC machining offers a high degree of customization, enabling the production of specialized components. Additionally, its scalability accommodates both low and high-volume production demands, making it a versatile choice for aerospace manufacturing.

Sustainability:

By minimizing material waste and enabling energy-efficient operations, Aerospace CNC machining is a step towards more sustainable manufacturing practices within the aerospace industry.

Aerospace CNC machining is crucial in the aerospace industry, ensuring precise, efficient, and high-quality production. As aerospace technology improves, CNC machining will also improve, pushing the limits of what can be done in aerospace manufacturing. Through Aerospace CNC machining, the sector is not only meeting the present-day challenges but is also gearing up for the future, ensuring sky is not the limit but just the beginning.

IN-X Machine, Inc.

IN-X Machine, Inc.